Swing Bearing PC200-5 PN 20Y-25-11103

SPECIAL ORDER ONLY 5-9 Week

Description

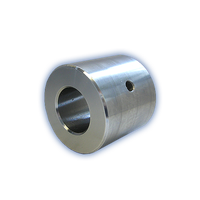

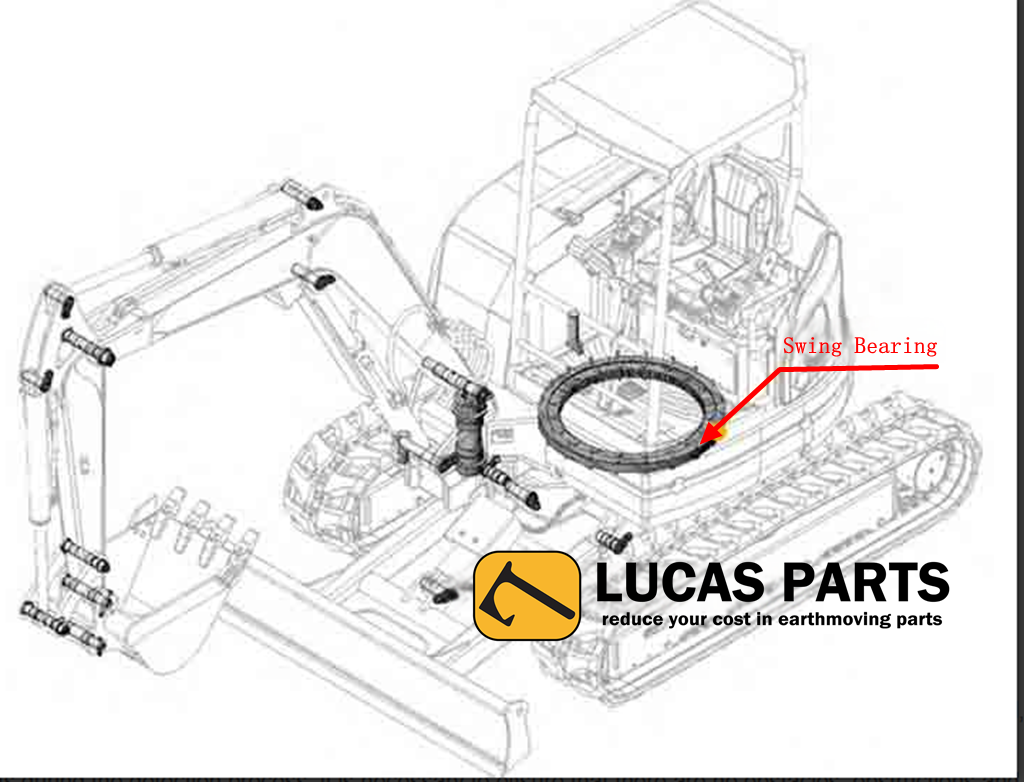

Premium Lucas Parts Swing Bearing (Slew Bearing/Slewing Ring) for Komatsu PC200-5

Ensure smooth and reliable rotation for your Komatsu PC200-5 excavator with this genuine Lucas Parts stock swing bearing (also known as a slew bearing or slewing ring). Designed for heavy-duty performance, this bearing minimizes wear and tear, providing long-lasting durability for demanding excavation work.

Key Features:

✅ OEM-Compatible Replacement – Perfect fit for Komatsu PC200-5

✅ Part Number: 20Y-25-11103

✅ High Load Capacity – Supports heavy-duty excavator movements

✅ Smooth Rotation – Reduces friction for efficient operation

✅ Corrosion-Resistant – Built to withstand harsh job site conditions

✅ Precision-Engineered – Ensures stability and longevity

Applications:

-

Komatsu PC200-5 Excavator

-

Excavator turntable rotation systems

-

Heavy machinery slewing mechanisms

Why Choose This Swing Bearing?

✔ Exact OEM Fit – No modifications required

✔ Enhanced Durability – High-grade steel construction

✔ Reduced Downtime – Reliable performance for continuous operation

A slew bearing (also known as a slewing ring/swing bearing/turntable bearing) is a type of rotational rolling-element bearing designed to handle heavy, slow-turning, or slowly oscillating loads. It supports combined load types—axial, radial, and moment loads—making it ideal for applications such as cranes, swing yarders, and the yaw mechanisms of horizontal-axis wind turbines, where it enables smooth rotation of horizontal platforms.

Lucas Parts slew bearings are engineered to handle heavy radial, thrust, and moment loads, with configurations available in non-gear or external gear designs. Backed by extensive expertise, our Swing Bearing delivers high-quality, custom-engineered slew bearings tailored to meet the precise demands of your applications.

Procedure for Inspecting Excavator Slewing Bearing Condition

To ensure safe and accurate inspection of the slewing bearing during excavator construction or maintenance, follow these steps:

Preparation & Positioning

-

Preparation & Positioning

-

Park the excavator on level ground, away from dust and debris.

-

Lower the front-end working device completely to the ground.

-

-

Safety Check

-

Clear the surrounding area of obstacles, obstructions, and unauthorized personnel to prevent accidents.

-

Verify that no potential hazards exist before proceeding.

-

-

Dial Indicator Setup

-

Secure the dial indicator frame to the lower frame.

-

Position the detection point approximately 20mm from the slewing seat ring.

-

-

Pre-Test Calibration

-

Reset the dial indicator to zero.

-

Fully extend the stick and retract the bucket to ensure proper alignment.

-

-

Measurement Process

-

Lower the bucket to the ground and raise the track 15-30cm above the surface.

-

Monitor the dial indicator and record three separate readings for accuracy.

-

Note: Variations in dial gauge positioning may affect measurements. Multiple recordings ensure data reliability and consistency.

Specifications

| SKU | EXSB20101A |

| Brand | Komatsu |

| Shipping Weight | 230.0000kg |

| Shipping Width | 1.200m |

| Shipping Height | 0.500m |

| Shipping Length | 1.200m |

| Shipping Cubic | 0.720000000m3 |

| Unit Of Measure | ea |

Reviews

Be The First To Review This Product!

Help other LUCAS PARTS users shop smarter by writing reviews for products you have purchased.